From factory floor to digital core

At the heart of this evolution is the move towards autonomous supply chains — intelligent, AI-powered systems that gather, analyse, and act on data in real time. These systems strengthen resilience, enabling rapid responses to shocks such as geopolitical instability, natural disasters, or volatile demand.

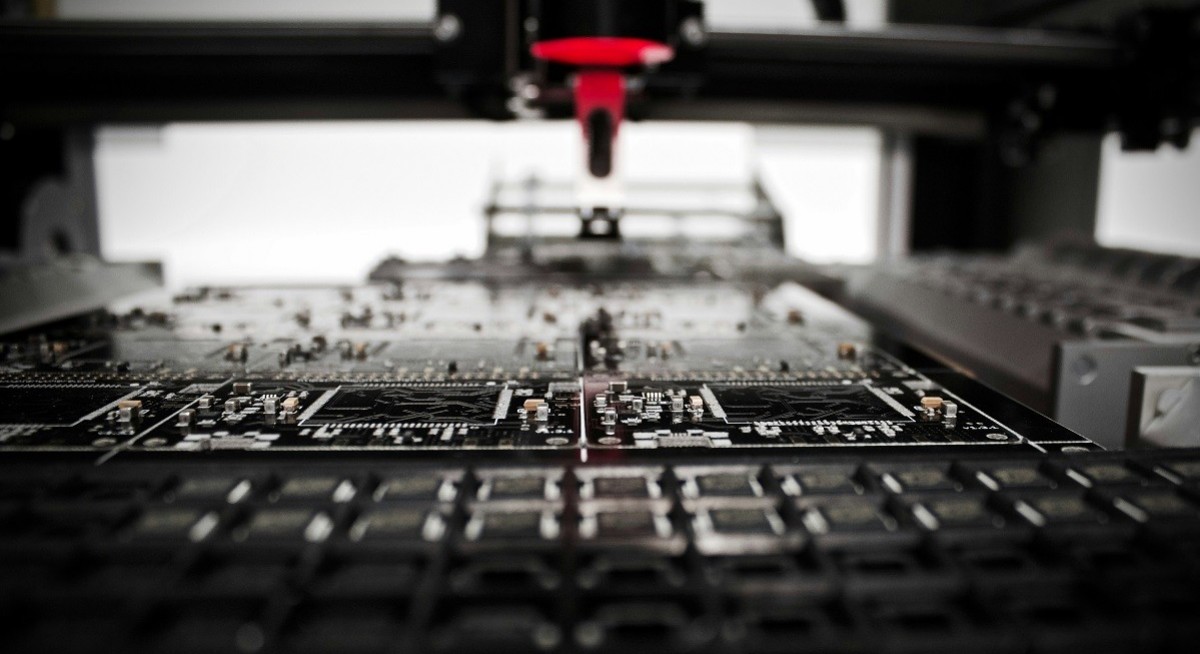

Singapore is uniquely placed to lead this shift. With robust infrastructure, forward-looking policies, and a highly skilled workforce, it is already home to leading manufacturers in semiconductors, pharmaceuticals, and precision engineering. Many are exploring agentic AI — next-generation models that autonomously reroute shipments, adapt to market changes, and mitigate risks with minimal human intervention.

AI-enabled digital twins, intelligent planning systems, and predictive analytics are becoming core to operations. For example, Asian food and beverage leader Yeo’s has adopted AI models for demand forecasting, enhancing forecast generation and operational efficiency. Though still early-stage, such use cases illustrate how AI can boost productivity and precision across industries.

See also: Microsoft’s new programme targets faster AI rollouts in Singapore

Building a future-ready workforce

The broader economic potential of AI lie not only in productivity gains but also in reshaping the skills and capabilities that define modern work. As manufacturing becomes increasingly digital, roles require deeper expertise in data analysis, systems thinking, and cross-functional collaboration.

Singapore’s SkillsFuture initiatives are playing a critical role here, enabling workers to upskill in robotics, analytics, and AI deployment. Partnerships between industry and academia are also creating new career pathways.

See also: AI race: Alphabet, Amazon, Meta and Microsoft set for US$650 bil capex this year

Small and medium-sized enterprises are advancing too, supported by initiatives such as the MNC–SME Alliance Program with the Singapore Manufacturing Federation, which helps firms raise digital maturity, strengthen resilience, and embrace Industry 5.0 technologies.

At the national level, the government’s National AI Stimulus Initiative, in partnership with Digital Industry Singapore (DISG), is accelerating enterprise adoption. Programmes such as the Enterprise Compute Initiative and AI Cloud Takeoff aim to establish AI Centres of Excellence in 300 digitally mature firms over the next year.

Singapore: Asean’s manufacturing nerve centre

As geopolitical tension drives companies to diversify sourcing, ASEAN has become an attractive base thanks to its talent, proximity to key markets, and expanding middle class. Within this shift, Singapore has emerged as the region’s hub for manufacturing innovation and supply chain command.

More firms are setting up regional control towers in Singapore, managing production across Thailand, Vietnam, and Indonesia with AI-enabled visibility. These hubs can simulate disruptions, predict material shortages, and adjust operations dynamically. For high-precision industries such as electric vehicles, pharmaceuticals, and medical technology, this “hub-and-spoke” model is critical. It not only enables speed and customisation but also creates high-value work in logistics, data, and advanced planning.

Building autonomous advantage with AI

Agentic AI is pushing supply chain autonomy beyond basic automation. These systems link with ERP platforms, draw on real-time external data such as weather or trade indices, and interact with other agents across networks. The result is a self-learning system that adapts and optimises continuously.

Sink your teeth into in-depth insights from our contributors, and dive into financial and economic trends

According to a recent IBM-Oracle-Accelalpha report, by 2026 over 60% of supply chain leaders expect AI agents to make proactive recommendations and reinvent workflows. But success depends not only on technology — it also relies on people, and on preparing them to collaborate with AI.

Manufacturers are embedding AI literacy at all levels, from shop floor operators to senior executives, while also investing in responsible AI practices. Human oversight remains vital to ensure safety, fairness, and transparency.

IBM’s own experience highlights the potential: applying AI to its supply chain has saved US$160 million through reduced inventory and optimised shipping, while also improving decision-making and speed.

Future-ready manufacturing for Singaporeans

The next wave of manufacturing in Singapore is about machines augmenting human capability. As workflows are redesigned, new roles will demand creativity, critical thinking, and collaboration.

Singapore’s ability to stay ahead will depend on sustained investment in technology, talent, and trust. Manufacturers must partner with technology and education providers, rethink job design, and embed sustainability from the outset. With the right ecosystem, manufacturing can once again become a career of choice — not for its legacy, but for the future it promises.

Juhi McClelland is managing partner of IBM Consulting Asia Pacific